R&D capability

The R&D capability of Thermal-Win Energy is a pivotal factor in establishing its competitiveness in the field of liquid cooling. The company's R&D team is led by renowned professors from universities, and the key R&D members include 4 PhDs and 6 masters. The team's expertise includes thermal and power engineering, electrical engineering, mechanical engineering, information engineering, software engineering, etc. Through years of accumulation of key technologies, Thermal-Win Energy possesses rapid upgrade capabilities, including both fundamental research and industrial application technology development. With the strong engine of "technology accumulation + iterative innovation + industrial implementation", Thermal-Win Energy achieves efficient promotion from technological prototypes to product implementation, balancing the innovation speed and market adaptability.

We have multiple independent intellectual property rights and technology patents, which form differentiated technical barriers and drive continuous business growth.

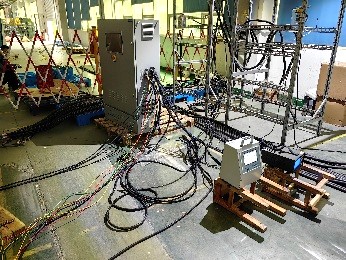

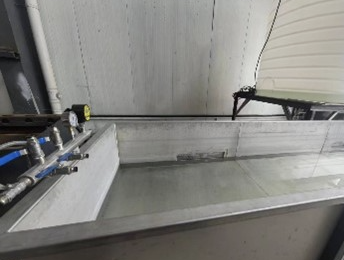

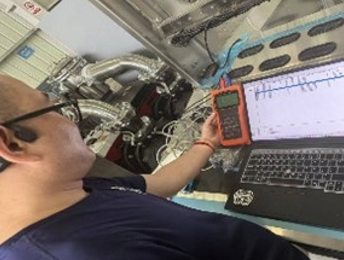

R&D testing center

Liquid cooling experiment

Work station

Electronic circuit test platform

Temperature rise test of control cabinet

CDU performance test

Manifold leakage test platform

GRUNDFOS E-Pump test

Flow and heat transfer uniformity testing

R&D capability

Thermal-Win Energy can design and manufacture the entire liquid cooling industry chain, including hardware processing: customized production of key components such as liquid cooling plates, air coolers, liquid cooling pipelines, pump/valve modules, distribution cabinets, electrical control cabinets, air-conditioners, PDUs, CDUs, etc.; Modular assembly: precise assembly of core components, pipeline connection, and sealing treatment based on the type of liquid cooling system (immersion type or cold plate type); Customized adaptation: customized system integration solutions to different power and spatial layout requirements such as high computing power data centers, AI supercomputing centers, intelligent computing centers, blockchain, and 5G base stations, etc.

TANK module production

Pipeline production

CDU module production

TANK sheet metal welding

Immersion cooling product manufacturing

Control cabine

Container-type production

Pack and ship